Precision Matthews 14×40 TS capable of holding tolerances to .0001″ is outfitted with a high pressure oil flush system that allows for quicker chambering and a superior surface finish.

Barrels are always indicated to within .0002″ concentric to the bore before work begins on both the chamber or muzzle end. Organization of tooling allows for an efficient operation.

All Metal work is properly prepped using 120 grit aluminum oxide and is degreased before being sprayed with Cerakote® H-Series finish. Parts are then baked in a custom built oven that ensures a fully cured finish that will hold up better than any firearms coating on the market.

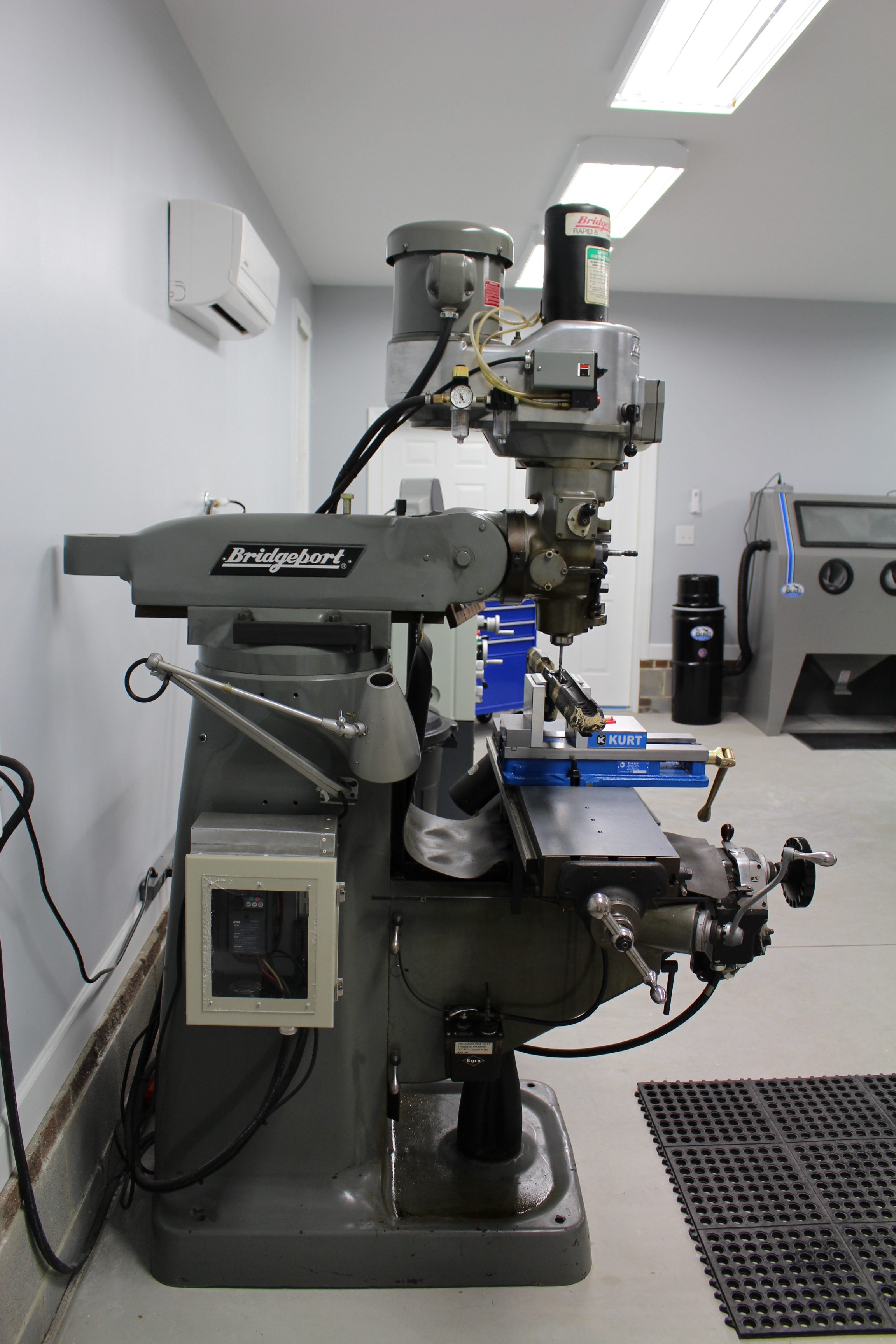

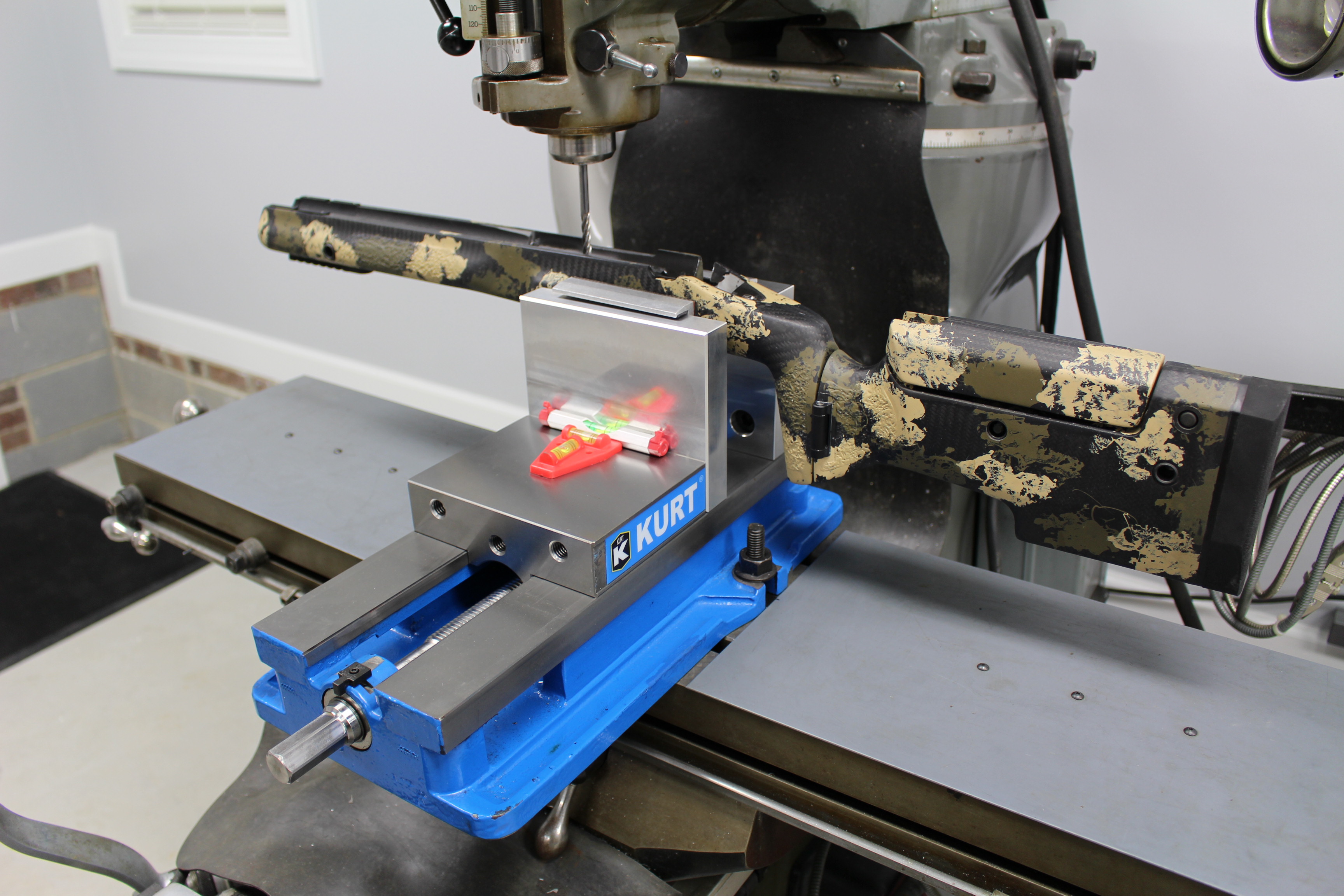

A Bridgeport 9×42 Mill that has been customized for gunsmithing work is primarily used to inlet stocks, clean up bedding, and modify actions.

Our Custom Paint Booth and Oven allow for the perfect application of Cerakote and Duracoat Finishes.